Here is Juno's solar set up with photos attached. We installed this in September of 2018 in preparing for our trip to the Bahamas for the Winter / Spring of 2019.

We had velcro flaps installed onto the bimini with matching velcro sewn onto the Solbian panels. The canvas shop recommended the flaps be made from TopGun instead of Sunbrella. TopGun is like a lightweight report cover. There are two pairs of Solbian SR-72Q-JB and Solbian SR-108-JB panels, one pair on starboard and one on port. Each pair has its own Victron 75/15 MPPT controller. I split into two pairs to avoid one string failure taking out all the solar. The Victron SE.Smart network pairs the two controllers electing one as a master so they don't fight each other trying to determine which mode to be in. I set the output voltage slightly below the setpoint for our Balmar alternator. This is to prevent the Balmar regulator from thinking that the bank is full and shutting down. Why? Well, when the regulator shuts down, the alarm on the ignition panel goes off.

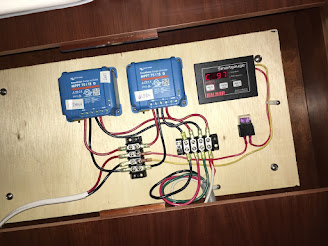

I used a four conductor 10 AWG cable to simplify wire management and needing only a single wire grommet in the deck. Splitting it into two separate cables might have been better as the four conductor cable is pretty beefy. The cable is led through the stern above the AC connections. I terminated the wires at a block just inside the aft lazarette so that I can disconnect and remove the outside cable when storing on the hard. I need to provide better protection for the terminal block. I took over the small cabinet in the aft cabin of our 423 for the MPPT controllers.

The velcro system seems very secure. We have never had any concern of loosing the panels. The've been in gusts to 45kts. If we are expecting tropical storm or hurricane winds we take the panels and bimini down. All that velcro is a little tricky to manage when mounting the panels as it keeps wanting to grab the panels before I have them positioned. I discovered that using a large piece plastic around a panel lets me get it into position, then I pull the plastic away and the velcro starts to grab. Mounting is also complicated because we have to do it with the bimini fully deployed so that it is stretched taut. A batten is useful for reaching the more distant flaps to separate the velcro.

Our largest single day production of power was 1,500 Wh in May in the Bahamas. We get 1,000 to 1,200 Wh in New England during the summer. The MPPT controllers claim that our max power production was 400W again in May in the Bahamas. New England summer we are seeing 280 - 300W max. I say claim because the total panel power is only 360W. The daily power is limited by how discharged our FLA batteries are and how fast they accept the charge.

I've seen discussions around concerns over durability of the flexible panels, especially when installed on a flexible surface like a bimini. So far so good. Hopefully Solbian will be around to stand behind their 5 year warranty.

When we were on our trip in the Bahamas we saw a boat fire caused by panels on their bimini. We didn't have any details but it is another consideration before installing directly on the bimini. It is suggested that the fires that have been caused by panels has been from "cheaper panels". I have no evidence to support or refute that claim.

Costs for the panels plus MPPT, and canvas work were $3,500 and $1,800 respectively. It was a lot more than I planned to spend on the canvas but we didn't have a lot of time to shop around, or to try DIY, which would probably have worked fine. The flexible panels are also a premium over fixed panels. Despite the cost we are very happy with the solution. We never had to run the engine for the purpose of recharging except when sailing at night once or twice. When our alternator was out of commission for a week, the solar kept us charged up and able to start the engine without a worry.

No comments:

Post a Comment